Water Softener Plant

Quality Satisfactions

Qualities will always vital at Right Water Systems Therefore it is imperative, at the company maintain an effective quality control to given all codes of Indian Standards , we always use the latest technology,

For easy Installation our units are unique mounted & completely packaged type with all required safeties & operating devices are supplied installed & pre tested in our works

We install entire (Fully Automatic as well as Semi-Automatic) on Turnkey basis.

1. ETP Plant Manufacture (Effluent Treatment Plant)

2. STP Plant Manufacture (Sewage Treatment Plant)

3. UF Plant Manufacture (Ultra Filtration Plant)

4. RO Plant Manufacture (Reverse Osmosis Plant)

5. ZLD Plant Manufacture (Zero Liquid Discharge Plant)

6. DM Plant Manufacturer (Demineralization Plant)

7. Swimming Pool Filtration System Manufacture

8. Package Drinking Water Plant Manufacture

9. Water Filtration Plant Manufacture

10. Softener Plant Manufacture

Water Treatment Chemicals (all Category of Water Treatment Chemicals)

All systems spares part available here any time

Scale build-up in pipes, resulting in decreased flow rates

Scale build-up on heating and cooling systems, leading to increased electricity costs and breakdowns.

White film on glass surfaces and staining on Water taps

Increased laundry costs due to hard Water reacting with soap and laundry detergents.

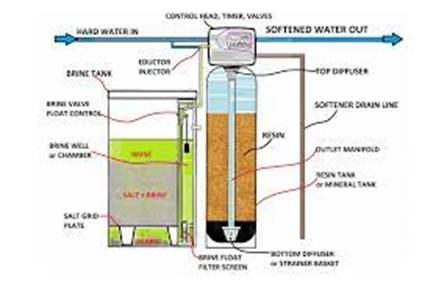

After producing desired output, the resin is regenerated with (NaCI) Sodium Chloride solution after which unit is again ready to deliver next batch. The Water Softening Plant units are available with different models. The difference between these models is in the capacity of the resin used for each model. These units are easy to operate and maintenance free. These models are available to produce various capacities up to 200 Cu. Meters per hour maximum.

The surface of the resin gets coated with the calcium and magnesium minerals. The resin is cleared by flushing a strong sodium (salt) solution held in the brine tank. The sodium ions are powerful and they easily overpower the calcium and magnesium ions and drives them off of the resins which is later drained out of the unit.

Automatic Water Softener Plant & Manual Water Softeners Plant

Chemical softeners are used in laundry. It basically removes magnesium and calcium and thus lengthen lifespan of clothes. However it should be kept in mind that the Water so treated is not fit for drinking.

Packaged Water Softeners :-

Packaged Water softeners are infect chemicals used for the softening purpose. There are two types of packaged Water softeners.

Precipitating and Non-precipitating:-

Washing soda and borax are the examples of precipitating Water softeners. These products upon reacting, forms insoluble precipitate with calcium and magnesium ions. This enhances the cleaning efficiency whereas, in Non-precipitating Water softeners, calcium and magnesium ions are segregated from the Water through complex phosphates.

Features:-

Automatic regeneration

User friendly

Require less space

Low power consumption

Reduction of scales

pipes and resin vessels

Increases the efficiency of appliances and the plumbing Systems.

Enhances service life

Light weight & compact

Anticorrosive parts

Efficaciously cleanses the harmful particles

Application:-

Boiler Feed.

Cooling Tower Make-Up.

Air Conditioning Plant.

Textile Processing.

Beverage Production.

Hospitals, Hotels, Laundries etc.

Food processing.

Chemical & textile.

Water power plants.

Ice plant.

Dyeing processes

Pharmaceutical industries

Product finishing

We design and manufacture very efficient Water softeners that are effective in reducing the hardness of the Water. They help in producing zero soft Water by highly acidic cation exchanger, which removes calcium and magnesium ions from the Water. our Water softener plant is portable, easy to move from one place to another.

It also involves less effort in terms of installation and maintenance. As one of the leading drinking Water softening plant manufacturers based in India, we make our products available to our customer’s at the most affordable price range.

PLANT INTRODUCTION: – The Proposed Water Treatment scheme designed to produce product water at the based on Water Softener Plant.

| S. No. | Parameters | Units | Results |

| BASIS OF RAW WATER DESIGN | |||

| 1 | pH at 25° C. | —– | |

| 2 | Suspended solids. | Ppm | < |

| 3 | BOD | Ppm | < |

| 4 | COD | Ppm | < |

| 5 | Calcium as Ca+2 | Ppm | < |

| 6 | Magnesium as Mg+2 | Ppm | < |

| 7 | Total Iron (as Fe) | Ppm | < |

| 8 | Sulphate as SO4-2 | Ppm | < |

| 9 | Nitrates as NO3- | Ppm | < |

| 10 | Phosphates as PO4-3 | Ppm | < |

| 11 | Fluorides as F- | Ppm | < |

| 12 | M-alkalinity as CaCO3 | Ppm | < |

| 13 | Total Silica as SiO2 | Ppm | < |

| 14 | Total Hardness as CaCO3 | Ppm | < |

| 15 | T.D.S | Ppm | < |

| 16 | Temperature | ° C | < |

| TREATED WATER PARAMETER QUALITY | |||

| 1 | Total Hardness | Ppm | < 5 |

| TREATED WATER | |||

| 1 | Treated Water Flow Rate | LPH | |

The end water quality shall to achieved subjected to:-

- Feed quality is same as specified in your enquiry. In case of any change in the quality of raw water, the same may have an implication on the Operating parameters and End- water quality of the system.

- Feed limiting condition mentioned in our offer strictly maintained.

Questionnaires for Water Softener / Water Treatment Plant:

1 Company Name, Address, Contact Person name and Tel No

2 Site address in detail where this plant is going to Install/ Operate

3 Source of Water- Lake/Well/Bore-well/Any other?

4 Total quantity of Soft Water required per day basis (This is required to set the OBR)

5 Inlet raw Water Hardness in mg/lit (OR attach raw Water analysis report)?

6 Usage of Water- Any specific purpose?

7 Output Water Quality in Terms Of Hardness in mg/lit?

Above data is compulsory to understand your requirement and to proceed further.