MB Plant

Quality Satisfactions

Right Water Systems is committed to the very best quality of its products to the complete satisfaction of its customers, our products and service quality are highly appreciated & accepted by the industry and customers. As a result, we always remain at the forefront of the industry and we have satisfied customers all over India.

Qualities will always vital at Right Water Systems Therefore it is imperative, at the company maintain an effective quality control to given all codes of Indian Standards , we always use the latest technology,

For easy Installation our units are unique mounted & completely packaged type with all required safeties & operating devices are supplied installed & pre tested in our works

Right Water Systems Present Few Category of Water Treatment Plant:-

We install entire (Fully Automatic as well as Semi-Automatic) on Turnkey basis.

1. ETP Plant Manufacture (Effluent Treatment Plant)

2. STP Plant Manufacture (Sewage Treatment Plant)

3. UF Plant Manufacture (Ultra Filtration Plant)

4. RO Plant Manufacture (Reverse Osmosis Plant)

5. ZLD Plant Manufacture (Zero Liquid Discharge Plant)

6. DM Plant Manufacturer (Demineralization Plant)

7. Swimming Pool Filtration System Manufacture

8. Package Drinking Water Plant Manufacture

9. Water Filtration Plant Manufacture

10. Softener Plant Manufacture

Water Treatment Chemicals (all Category of Water Treatment Chemicals)

All systems spares part available here any time

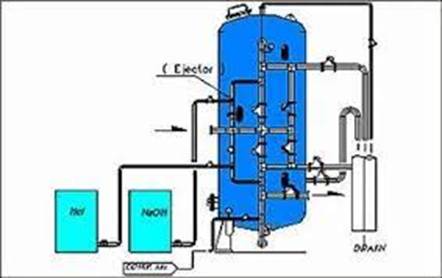

Mixed-bed deionization:

In mixed-bed deionizers the cation-exchange and anion-exchange resins are intimately mixed and contained in a single pressure vessel.

The thorough mixture of cation-exchangers and anion-exchangers in a single column makes a mixed-bed deionizer equivalent to a lengthy series of two-bed plants. As a result, the Water quality obtained from a mixed-bed deionizer is appreciably higher than that produced by a two-bed plant. Although more efficient in purifying the incoming feed water, mixed-bed plants are more sensitive to impurities in the Water supply and involve a more complicated regeneration process. Mixedbed deionizers are normally used to ‘polish’ the Water to higher levels of purity after it has been initially treated by either a two-bed deionizer or a reverse osmosis unit.

Ion-exchange resin

An ion-exchange resin or ion-exchange polymer is a resin or polymer that acts as a medium for ion exchange. It is an insoluble matrix (or support structure) normally in the form of small (0.25–1.43 mm radius) microbeads, usually white or yellowish, fabricated from an organic polymer substrate. The beads are typically porous (with a specific size distribution that will affect its properties), providing a large surface area on and inside them where the trapping of ions occurs along with the accompanying release of other ions, and thus the process is called ion exchange. There are multiple types of ion-exchange resin. Ion-exchange resins are widely used in different separation, purification, and decontamination processes. The most common examples are water softening and water purification. In many cases ion-exchange resins were introduced in such processes as a more flexible alternative to the use of natural or artificial zeolites. Also, ionexchange resins are highly effective in the biodiesel filtration process.

All types Valve

Right Water Systems Our wide range of multiport valves are designed for various filtration/softening applications. They provide excellent performance with a simple customer-friendly operation. A simple turn of the handle performs multiple functions like filtration, backwash, rinse, brine suction and brine rinse. These valves are also aesthetically designed to give an excellent appearance to the final system. The innovative new generation models offer a convenient and unique inlet and outlet in the same line feature for filters and softeners.Features

Front facing type filters and softeners Sky facing type filters and softeners Side mount/Centre Mounted filter and softener New Generation with inlet and and outlet in the same line for filters and softeners

| TECHNICAL SPECIFICATIONS: | |

|---|---|

| Material of Construction | Engineering Thermoplastic |

| Maximum Flow Rate | 1800lph @ 0.5 Kg/cm2 pressure drop |

| Valve Connection to Vessel | 3/4” BSP Adaptors provided |

| Riser Pipe Size | 25mm OD PVC pipe |

| Inlet, Outlet, Drain Connections | 3/4” BSP(F) |

| Regeneration Suction Tubing | 1/4″ |

| Ejector Type | In-built |

| Injector Ratio | 1:1 |

| Injector Suction Rate | 400 lph |

| Maximum Operating Pressure | 4 Kg/cm2 |

| Minimum Pressure for Uniform Suction | 3 Kg/cm2 |

| Accessories | Top and bottom disc type strainer, Suction tubing and foot valve for softeners only |

Operating Procedure:

Ensure prior to start up – First time after every maintenance:

Ensure that Activated carbon filter, Cation, Anion, Mix bed, Vessel is filled with specified and required quantity resin.

Ensure that the all valves are in operation.

Check that all piping work is carried as per its piping drawing given in manufacturer’s manual.

Ensure that there is no water leakage.

Ensure that the DM plant feed water pump gives rated flow and Pressure required for DM plant.

Test the water inlet quality. It should be as per specification given in design data.Ensure raw water pressure at the inlet is not less

than 1.7-2 kg/cm2

Starting Procedure / Instruction of DM Plant

Open the GIDC raw water inlet valve leading to the suction line of

the DM plant feed water pump.

Switch ON the DM plant feed water pump.

Slowly open the pump discharge valve leading to the inlet valve of

The DM plant.

Open the Cation inlet valve V1.

Open the Anion inlet valve V5 and rinse outlet valve V7

Adjust V7 to get specified rinse flow to drain.

Open valve V12 to allow some flow through the conductivity cell.

Switch ON the conductivity meter to ‘CALIBRATE’

If the needle on meter indicates exactly 40, move to ‘READ’

position

Acid Rinse:

Adjust valve V3 to maintain specified flow for the specified time.

At the end of this specified period, it is advisable to take a sample

from valve V10 and test it for pH with the help of pH strip.

If the result of the test is satisfactory, close valves V10 and V3.

Stopping Procedure / Instruction of DM Plant

Switch OFF the conductivity meter.

Switch OFF the DM water feed pump.

Close the Anion outlet valve V6.

Close the Anion inlet valve V5.

Close the Cation inlet valve V1.

Close the GIDC inlet raw water valve.

Acid Injection:

Prepare the stipulated quantity of acid + dematerialized water

Solution by stirring in the measuring tank.

Open the main raw water inlet valve V1, acid ejector power water

valve V3.

Open the acid outlet valve V10.

Open the acid ejector suction valve V4.

Adjust V3 to maintain the specified flow to drain, such that the

acid

The measuring tank is emptied in the specified time, leaving only a

dead

Level of 25 mm in the tank.

Now close valve V4.

Soda Injection:

Prepare the stipulated quantity of caustic soda + dematerialized

water solution by stirring in the measuring tank.

Open the main raw water inlet valve V1, caustic ejector power

water valve V8.

Open the caustic outlet valve V11.

Open the caustic ejector suction valve V4.

Adjust V8 to maintain the specified flow to drain, such that the

acid

measuring tank is emptied in the specified time, leaving only a

dead

level of 25 mm in the tank.

Now close valve V9.

Soda Rinse:

Adjust valve V3 to maintain specified flow for the specified time of 30 min.. At the end of this specified period, close valves V8 and V11.Stopping Procedure / Instruction of DM Plant

Switch OFF the conductivity meter.

Switch OFF the DM water feed pump.

Close the Anion outlet valve V6.

Close the Anion inlet valve V5.

Close the Cation inlet valve V1.

Close the GIDC inlet raw water valve.

Acid Injection:

Prepare the stipulated quantity of acid + dematerialized water

Solution by stirring in the measuring tank.

Open the main raw water inlet valve V1, acid ejector power water

valve V3.

Open the acid outlet valve V10.

Open the acid ejector suction valve V4.

Adjust V3 to maintain the specified flow to drain, such that the

acid

The measuring tank is emptied in the specified time, leaving only a

dead

Level of 25 mm in the tank.

Now close valve V4.

Final Rinse:

Open valve Anion inlet valve V5 and final rinse outlet valve V7.

After @ 20 minutes, open conductivity cell isolation valve V12

Switch ON the conductivity tester. Reading must be below 30

uS/cm.

Close final rinse outlet valve V7.

Open Anion outlet valve V6 to send DM water to service.

After 30 to 40 minutes we can get an acceptable level of

conductivity

Ensure prior to start-up of Mixed Bed Unit – Only first time:

Ensure that mixed bed vessel is filled with specified and required

quantity resin.

Ensure that the all valves are in operation.

Check that all piping work is carried as per the piping drawing

given in manufacturer’s manual.

Ensure that there is no water leakage.

Ensure the specified flow rate.

Test the water inlet quality. It should be as per specification given

in design data.

Chemical Required For Regeneration (Cation & Anion)

HCL for Cation-100% (4.40 Kg. / Regeneration) 80gm/Ltr. Resin

NaOH for Anion- 100% (3.85 Kg. / Regeneration) 70gm/Ltr. Resin

Chemical Required For Regeneration (MB)

HCL for Cation-100% (0.80 Kg. / Regeneration) 80gm/Ltr. Resin

NaOH for Anion- 100% (1.00 Kg. / Regeneration) 70gm/Ltr. Resin